The Golden Ratio

Technion scientists have created a porous, single crystal of gold - Prof. Boaz Pokroy

For the first time ever, Technion researchers managed to grow a porous single crystal of gold.

The study, published on November 10 issue of the journal Nature Communications, was conducted by doctoral student Maria Koifman Khristosov, a student in the Norman Seiden Multidisciplinary Graduate Program in Nanoscience and Nanotechnology, under the guidance of Prof. Boaz Pokroy of the Faculty of Science and Materials Engineering and a member in the Russell Berrie Nanotechnology Institute.

Crystalline material may be multi-crystal or single-crystal. A single crystal is a substance made up of atoms arranged in a long-term periodic arrangement, while a multi crystal is made up of single crystals. Multi crystals have different characteristics from those of single crystals – the difference arising from the different arrangement of atoms. Single crystals are not a human invention; they exist in nature in various materials. A diamond, for example, is a single crystal of carbon.

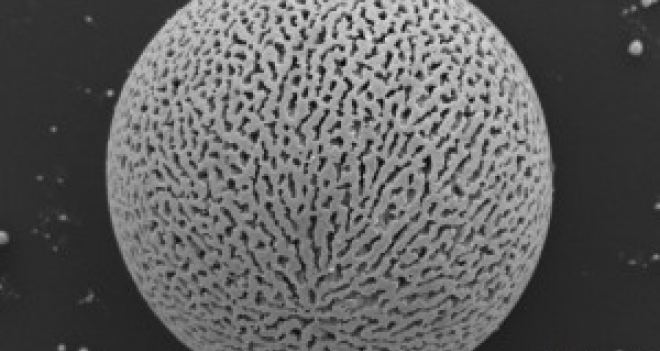

In nature there are organisms capable of creating single crystals that look non-crystalline, i.e. rounded in shape with no straight facets. Sometimes these crystals are porous. “In nature there are crystals with highly complex shapes and with no facets at all, and they are actually a single crystal,” says Prof. Pokroy. “For example, the spines of a sea urchin are single crystals. People who are not experts on the subject will find it hard to believe that these are single crystals.” Artificial single crystals produced (grown) in the laboratory are generally characterized by a more ‘crystalline’ appearance, i.e. with clear facets.

Up to now, rounded and porous crystals like those in nature have hardly ever been grown in the laboratory, because this production process is a highly complex scientific and engineering challenge. “Of course one can produce ‘crystalline’ single crystals in the laboratory and then process them until they reach the desired complex shape, but this is an expensive and prolonged process, and is actually impossible when we ultimately want to obtain a porous crystal. Therefore, considerable effort is being invested in developing methods for growing single crystals.”

Advantages include mechanical strength, high resistance to heat and enhanced conduction of electricity and heat.

The Technion researchers’ success in growing a porous crystal in the laboratory is based on an innovative process developed by Professor Pokroy and Maria Koifman Khristosov: thermal treatment of thin layers of gold and germanium. This treatment creates liquid droplets tens of microns in size. Cooling the droplets enables the gold to crystallize, creating a single nucleation point, and this is how a porous single crystal is formed. Thorough testing of the product, using advanced equipment at the Technion Electron Microscopy Center, reveals that these are single crystals containing channels tens of nanometers in diameter. “Our motivation in developing the new technology is purely scientific,” explains Maria Koifman, “but these materials clearly have many potential applications. Single crystals have many advantages resulting from the absence of the nuclear boundaries characteristic of ‘normal’ crystals. These advantages include mechanical strength, high resistance to heat and enhanced conduction of electricity and heat.”

The study is being carried out with the support of the Technion’s Russell Berrie Nanotechnology Institute, funded by an ERC grant given to Prof. Pokroy by the European Union, and in cooperation with the accelerator (the European Synchrotron Radiation Facility) in Grenoble, France.

Prof. Pokroy earned three degrees at the Technion Faculty of Science and Materials Engineering, and returned to the Technion in 2009 after a post-doc at Harvard (under the guidance of Prof. Joanna Aizenberg) and Bell Labs. “My stay in the US was very interesting,” he says, “and I was happy to get a job here in Israel on my return. Two other significant incentives to return were the prestigious Allon Fellowship for Outstanding Young Researchers and the opportunity to be part of the Technion’s Russell Berrie Center.”

He has only good things to say about the students at the Technion – “They are just as good as the students at Harvard.” The Pokroy team consists of nine graduate students. Prof. Pokroy’s involvement with nature-inspired materials engineering began with his doctorate, under the guidance of Prof. Emil Zolotoyabko, “In many cases nature surpasses us, the engineers, in terms of the products that it produces. I focus on bio-mineralization – i.e. studying the mechanisms in which organisms form minerals. It is important to note that I am studying these processes not in order to imitate them, as is done in the field of biomimetics, but rather to gain inspiration for applied engineering processes. Therefore, I call it Bio-inspired engineering. One of my goals is practical, and it is to discover how to create surfaces and composites with enhanced characteristics inspired by nature.

The research is being carried out in collaboration with the Russell Berrie Nanotechnology Institute (RBNI)